In today's rapidly advancing technological landscape, the demand for high-performance electronic components is on the rise, making the exploration of various options for the best Pcb Flex Board both critical and exciting. These flexible printed circuit boards are revolutionizing the design and functionality of electronic devices, offering unparalleled flexibility, lightweight structures, and the ability to fit into tight spaces. As global manufacturing continues to thrive, particularly in China, we take pride in producing world-class Pcb Flex Boards that are not only innovative but also cater to diverse industry needs.

This blog will delve into the promising options available for achieving optimal flexibility and functionality in Pcb Flex Board design, showcasing the technological advancements and manufacturing prowess that place Chinese products on the global stage. Join us as we uncover the transformative capabilities of these essential components, highlighting how they support the future of electronics worldwide.

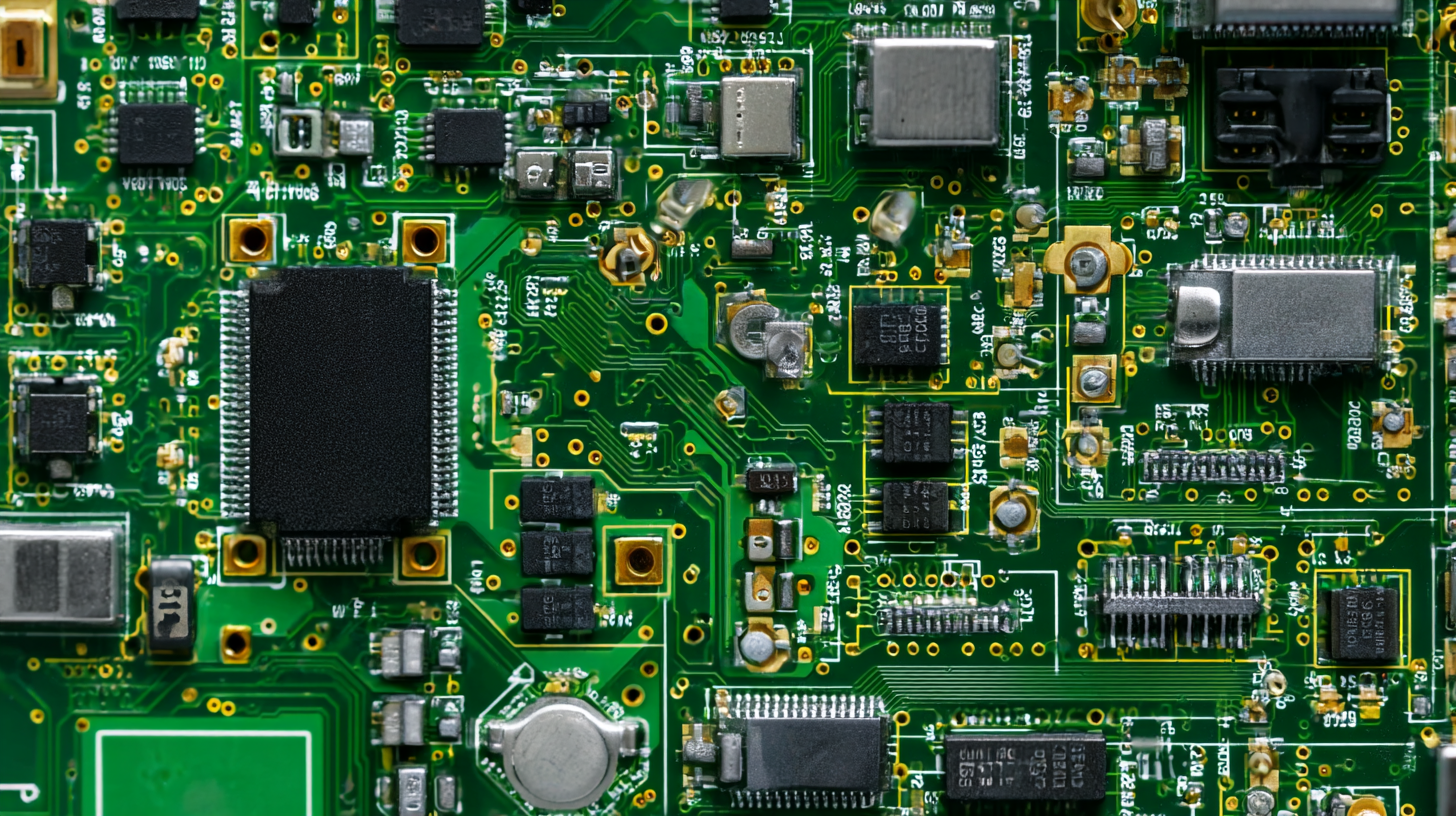

PCB flex boards, or flexible printed circuit boards, offer a unique combination of flexibility and functionality that traditional rigid boards cannot match. These boards are constructed from flexible materials that allow them to bend and twist, making them ideal for compact and dynamic applications. According to a report by MarketsandMarkets, the global flexible printed circuit board market is projected to reach USD 33.3 billion by 2023, driven by the increasing demand in consumer electronics, automotive systems, and medical devices. This growth is a testament to their critical characteristics, such as lightweight design and the ability to fit into tight spaces, enhancing overall device performance and efficiency.

PCB flex boards, or flexible printed circuit boards, offer a unique combination of flexibility and functionality that traditional rigid boards cannot match. These boards are constructed from flexible materials that allow them to bend and twist, making them ideal for compact and dynamic applications. According to a report by MarketsandMarkets, the global flexible printed circuit board market is projected to reach USD 33.3 billion by 2023, driven by the increasing demand in consumer electronics, automotive systems, and medical devices. This growth is a testament to their critical characteristics, such as lightweight design and the ability to fit into tight spaces, enhancing overall device performance and efficiency.

One of the key benefits of PCB flex boards is their ability to improve reliability and reduce assembly errors. A study by IPC reveals that flexible circuits can help decrease the number of interconnects, leading to fewer solder joints and potential points of failure. Additionally, the self-aligning nature of flex circuits allows for easier integration into multi-layer assemblies, streamlining manufacturing processes. This versatility makes them a preferred choice for sectors requiring high durability and performance, including aerospace and telecommunications, where environmental and operational stresses on components are significant.

When evaluating PCB flexibility, several key factors should be taken into consideration to strike the right balance between flexibility and functionality. One crucial aspect is the choice of materials used in the PCB construction.

Flexible circuit boards are typically made from polyimide or polyester substrates, which offer different degrees of flexibility and thermal stability. Selecting the appropriate material can significantly affect both the bending capabilities and the overall performance of the circuit.

Flexible circuit boards are typically made from polyimide or polyester substrates, which offer different degrees of flexibility and thermal stability. Selecting the appropriate material can significantly affect both the bending capabilities and the overall performance of the circuit.

In addition to material selection, the thickness of the PCB plays a vital role in its flexibility. Thinner boards tend to be more pliable, allowing for tighter bends and more creative design possibilities. However, reducing thickness may compromise the board's structural integrity and durability. Therefore, it is essential to determine the optimal thickness based on the specific application requirements.

Tips: When designing your PCB, consider implementing embedded components or using rounded corners to enhance flexibility without sacrificing performance. Additionally, test prototypes under various conditions to ensure they withstand the intended use while maintaining their flexible properties. Finally, consult with manufacturing experts to optimize your design for both functionality and flexibility, ensuring a successful outcome for your project.

When designing flex circuits, several critical considerations must be addressed to ensure optimal functionality and performance. The choice of materials is paramount; flexible substrates like polyimide or polyester can significantly affect the board's durability and flexibility. Additionally, the thickness of the copper traces is essential, as thicker traces provide improved conductivity but can compromise flexibility. Designers must strike a balance between conductivity and bendability, particularly in applications where the circuit will experience frequent movement.

Another crucial design aspect is the layout of components. Engineers should prioritize the positioning of sensitive components to minimize stress concentrations that can lead to failure over time. Utilizing a gradual bend radius and avoiding sharp turns in the circuit design can enhance durability. It's also important to consider the impact of environmental factors, such as temperature variations and exposure to chemicals, which can influence the overall lifespan and reliability of the flex circuit. By carefully evaluating these design considerations, engineers can create flexible PCBs that not only meet functional requirements but also withstand the rigors of their intended applications.

When it comes to designing flexible printed circuit boards (PCBs), material selection plays a pivotal role in achieving the desired flexibility and performance. The ideal materials not only facilitate bending and twisting but also ensure reliable electrical conductivity. Polyimide is one of the most commonly used substrates due to its excellent thermal stability and mechanical properties. This polymer can withstand high temperatures, making it an ideal choice for applications in harsh environments.

In addition to polyimide, other materials such as polyester and thermoplastic elastomers (TPE) are gaining popularity for their unique benefits. Polyester offers good flexibility and is generally more cost-effective, while TPEs provide superior durability and flexibility, making them suitable for longer-lasting applications. By carefully evaluating the requirements of your project, including factors like environmental conditions and mechanical stress, you can select the optimal material that balances flexibility and performance, ultimately enhancing the functionality of your PCB flex board.

| Material Type | Flexibility Rating | Temperature Resistance (°C) | Dielectric Strength (kV/mm) | Applications |

|---|---|---|---|---|

| Polyimide (PI) | High | 260 | 20 | Aerospace, Robotics |

| Polyester (PET) | Medium | 130 | 15 | Consumer Electronics |

| Polyvinyl Fluoride (PVF) | Medium | 150 | 18 | LED Lighting, Smart Devices |

| Liquid Crystal Polymer (LCP) | Very High | 260 | 30 | Telecommunications, Automotive |

Flexible printed circuit boards (PCBs) have become increasingly vital in modern technology due to their ability to adapt to a variety of applications. These versatile boards can be bent, twisted, and contoured, making them ideal for use in compact spaces where traditional rigid boards might fail. In devices such as smartphones, wearable technology, and medical equipment, flex boards ensure not only a lightweight design but also enhance functionality by accommodating intricate layouts and interconnections.

One notable real-world application of flexible PCBs is in the automotive industry, where they are used in advanced driver-assistance systems (ADAS). In these systems, the compact and lightweight nature of flex boards enables the integration of numerous sensors, cameras, and control units, all working together to improve safety and performance. Additionally, as the trend towards electric vehicles (EVs) grows, flexible PCBs play a critical role in the integration of power management systems and battery monitoring, illustrating their indispensable contribution to modern technological innovations.