In the rapidly evolving electronics landscape, Rigid Flex Boards have emerged as a critical component driving innovation across various industries. According to a recent industry report by MarketsandMarkets, the global flexible printed circuit (FPC) market is projected to reach $40 billion by 2025, with Rigid Flex technology playing a pivotal role in this growth due to its unique advantages of high-density interconnects and enhanced durability. As consumer demand for more compact and efficient electronic devices increases, manufacturers are increasingly adopting Rigid Flex Boards to optimize performance while minimizing space. This blog delves into the top five technical specifications of Rigid Flex Boards that are essential for anyone looking to navigate the future of electronics, aligning with industry trends and top strategies for 2025.

In the rapidly evolving electronics landscape, Rigid Flex Boards have emerged as a critical component driving innovation across various industries. According to a recent industry report by MarketsandMarkets, the global flexible printed circuit (FPC) market is projected to reach $40 billion by 2025, with Rigid Flex technology playing a pivotal role in this growth due to its unique advantages of high-density interconnects and enhanced durability. As consumer demand for more compact and efficient electronic devices increases, manufacturers are increasingly adopting Rigid Flex Boards to optimize performance while minimizing space. This blog delves into the top five technical specifications of Rigid Flex Boards that are essential for anyone looking to navigate the future of electronics, aligning with industry trends and top strategies for 2025.

When it comes to achieving optimal performance in rigid flex boards, key material considerations play a pivotal role. Recent advancements in design tools have enabled engineers to specify multiple rigid and flex stack-ups within the same framework, enhancing the versatility of these boards. According to industry reports, the right choice of materials can significantly influence factors such as electrical performance, durability, and overall product lifespan. For instance, using a polyimide film substrate can improve flexibility while maintaining thermal stability, essential for applications in compact spaces.

Moreover, the mechanical properties of the materials used are crucial for enduring the rigorous demands of flexible electronics. Studies suggest that incorporating high-performance electrodes, tailored for elasticity and biocompatibility, can enhance the functionality of wearable devices. This indicates that selecting the right materials not only affects the physical properties of the boards but also their compatibility with emerging technologies. A meticulous approach to material selection will ultimately ensure better performance metrics like signal integrity and thermal efficiency, making it indispensable for today's engineers in the field of rigid flex board design.

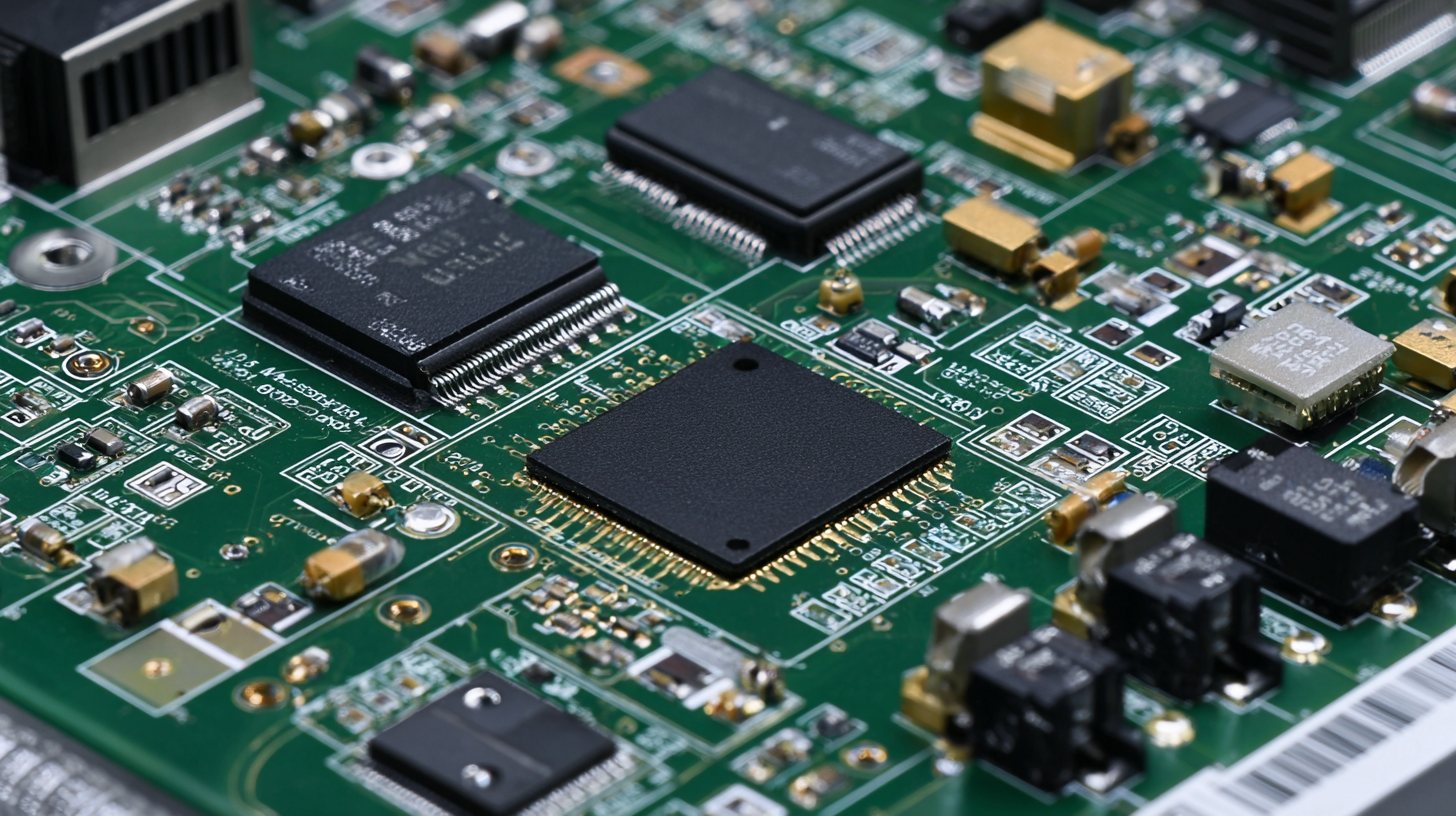

When it comes to designing high-performance electronic devices, understanding the essential layer configuration of rigid flex boards is crucial. Rigid flex technology combines the best of both rigid and flexible circuit boards, offering unique advantages such as weight reduction and space efficiency. According to a 2023 market report by IDTechEx, the rigid flex PCB market is expected to grow by 8.5% annually as manufacturers increasingly recognize these advantages in sectors like automotive and aerospace.

A key factor in enhancing circuit functionality is the use of appropriate layer configurations. The optimal number of layers often depends on the application; for example, multi-layer configurations typically enable greater signal integrity and reduce electromagnetic interference. Industry experts suggest that for more complex designs, a 4 to 6-layer configuration can significantly improve performance, allowing dense interconnections with minimal size.

Tips: Consider utilizing techniques such as controlled impedance design to enhance signal integrity in your rigid flex boards. Additionally, optimizing the stacking sequence of your layers can lead to better thermal management and lower manufacturing costs. As the demand for compact, high-performing circuits continues to rise, getting the layer configuration right is more important than ever.

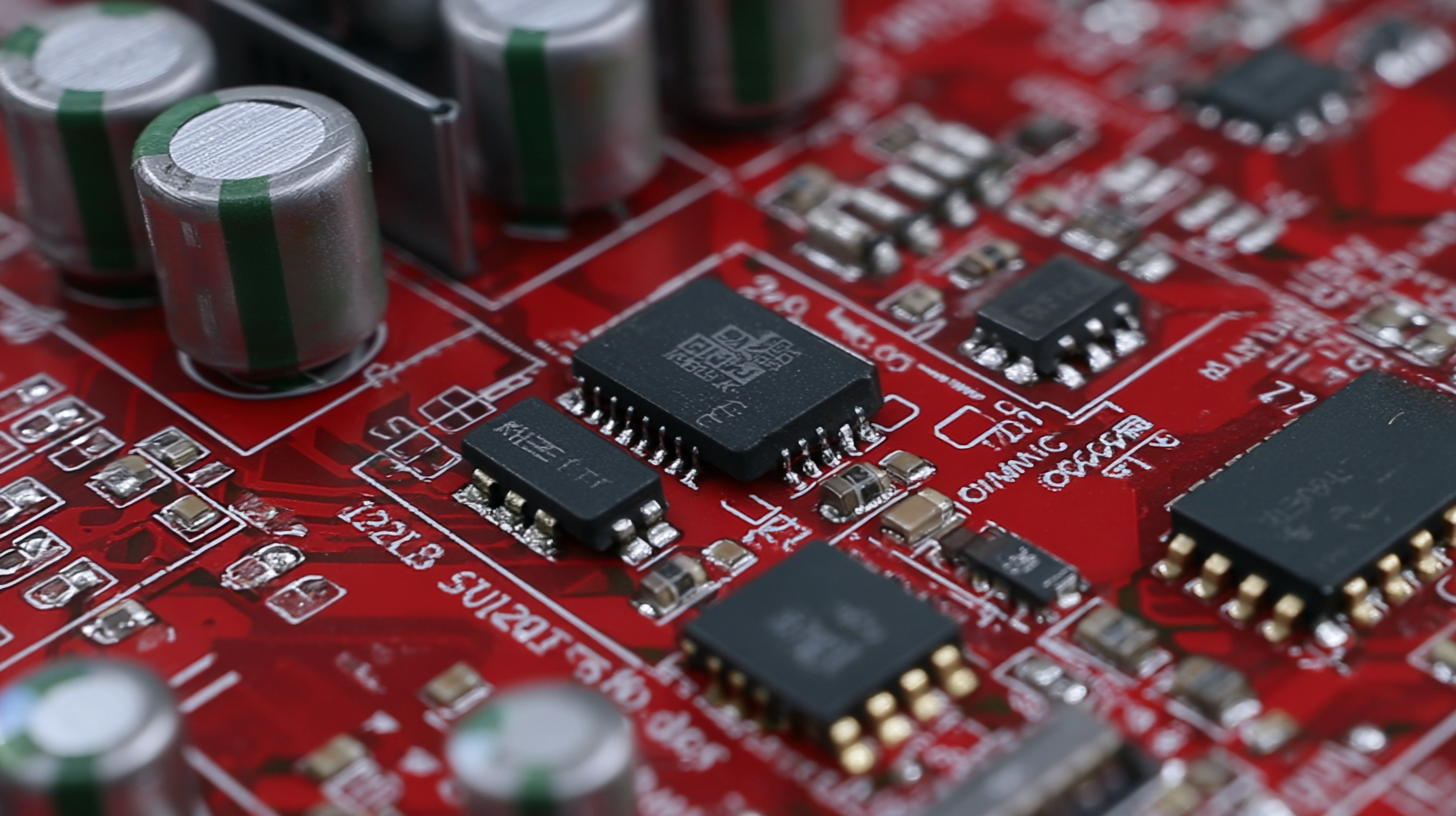

Surface finish plays a crucial role in the reliability and performance of rigid flex boards. With the increasing complexity of electronic devices, the demand for high-quality surface finishes has surged. According to a report by IPC (Institute for Printed Circuits), about 70% of failures in rigid flex applications can be traced back to surface finish issues. Common finishes such as HASL (Hot Air Solder Leveling) and ENIG (Electroless Nickel Immersion Gold) each have distinct impacts on the board’s durability and solderability, which are key factors in ensuring long-term performance.

The choice of surface finish directly influences not just the initial assembly processes but also the operational lifespan of the rigid flex boards. Research indicates that ENIG, for example, offers superior corrosion resistance and better solderability compared to HASL, leading to a 30% improvement in the reliability of interconnections in certain applications. As manufacturers aim for higher integration and smaller form factors, investing in advanced surface finishes becomes essential to meet the stringent industry standards. This enhances both the electrical performance and the mechanical integrity of the boards, ensuring they can withstand the rigors of modern electronic applications.

| Specification | Value | Impact on Reliability |

|---|---|---|

| Layer Count | 4-12 Layers | Higher layer count enhances electrical performance and thermal management. |

| Minimum Trace Width | 3-5 mils | Smaller traces reduce the chance of short circuits and improve signal integrity. |

| Surface Finish | ENIG (Electroless Nickel Immersion Gold) | Provides excellent solderability and protects against oxidation, increasing longevity. |

| Base Material | FR-4 or Polyimide | Choosing the right material influences thermal stability and flexibility, impacting overall reliability. |

| Thermal Conductivity | 1.0 - 2.0 W/mK | Higher thermal conductivity helps in heat dissipation, preventing component failure. |

When designing a rigid flex board, understanding the bend radius is crucial for achieving optimal performance and flexibility. The bend radius refers to the minimum radius that a circuit board can be bent without risking damage or failure.

According to the IPC-2223 standard, the ideal bend radius should be at least 3-5 times the thickness of the board to ensure that it can endure flexing without compromising electrical connections or structural integrity.

In a market report by Gartner, about 40% of engineers reported that improper bend radius was a leading cause of board failure in flexible circuit designs. This highlights the importance of selecting the right specifications when fabricating rigid flex boards.

Additionally, a bend radius that’s too tight can lead to issues such as micro-cracking and delamination, ultimately impacting the reliability of the device.

Thus, careful consideration of the bend radius not only enhances design flexibility but also prolongs the lifespan of electronic products in the rapidly evolving tech landscape.

Thermal management plays a critical role in the reliability and longevity of rigid flex circuits, which have become increasingly vital in various applications from consumer electronics to automotive systems. According to the IPC (Institute of Printed Circuits), effective thermal management can improve circuit lifespans by up to 30%, addressing the thermal stresses that occur in high-density and multi-layer PCB designs. Rigid flex circuits, with their unique combination of rigid and flexible materials, inherently face challenges related to thermal expansion and heat dissipation.

One technique gaining traction is the use of thermal interface materials (TIMs). Recent studies indicate that advanced TIMs can reduce thermal resistance by up to 50%, significantly enhancing heat transfer from components to substrates. Additionally, the implementation of copper heat sinks and innovative routing strategies has proven effective, as noted in a 2022 report by the Electronics Cooling Magazine, which highlighted a reduction in operational temperatures by up to 20% when appropriately applied in rigid flex designs. These advancements enable manufacturers to create more robust and reliable products that withstand varying operational conditions, ultimately delivering higher performance in demanding applications.